Departments

Mechanical & Metallographic Laboratory

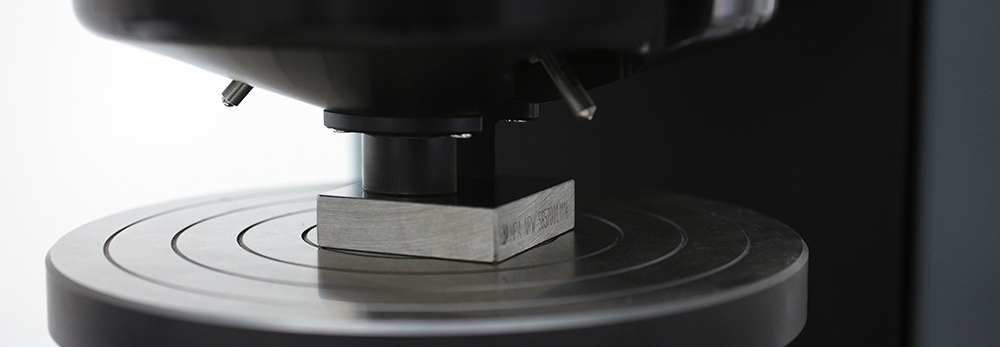

Hardness Test is applied to measure the resistance of the materials against plastic deformation. Durascan 70 and Duravision 40 devices are used for hardness tests at Çimtaş Mechanical and Metallographic Test Laboratory.

4 Different Methods are used;

- Vickers Hardness Measurement Method: A pyramid-shaped tip with a square base is immersed on the surface of the material with a specific load and then diagonal of the mark is measured, the hardness value in Vickers is calculated.

- Brinell Hardness Measurement Method: It is a method based on the application of a specific load to the surface of the material with the help of a specific circular tip and measurement of the mark on the surface.

- Rockwell Hardness Measurement Method: A load of 10 kg is applied on the material first, then the major test load is applied. The difference in depth between the two applications on the surface of the material gives Rockwell hardness of the material.

- Knoop Hardness Measuring Method: A tip in the form of a pyramid is used. Knoop hardness of the material is calculated by performing a calculation according to the surface trace.

Test Standards;

- TS EN ISO 6507-1

- TS EN ISO 9015-1

- ASTM E384

- ASTM E10

- TS EN ISO 6506-1

- ASTM E18

- TS EN ISO 6508-1

- ASTM E92