Production

Production

Multiple production features and solutions for handling wide range of pipe diameter & thickness combinations;

- JCO Bending > Post Bending > Calibration & Straightening

- Edge Crimping > JCO Bending > Calibration & Straightening

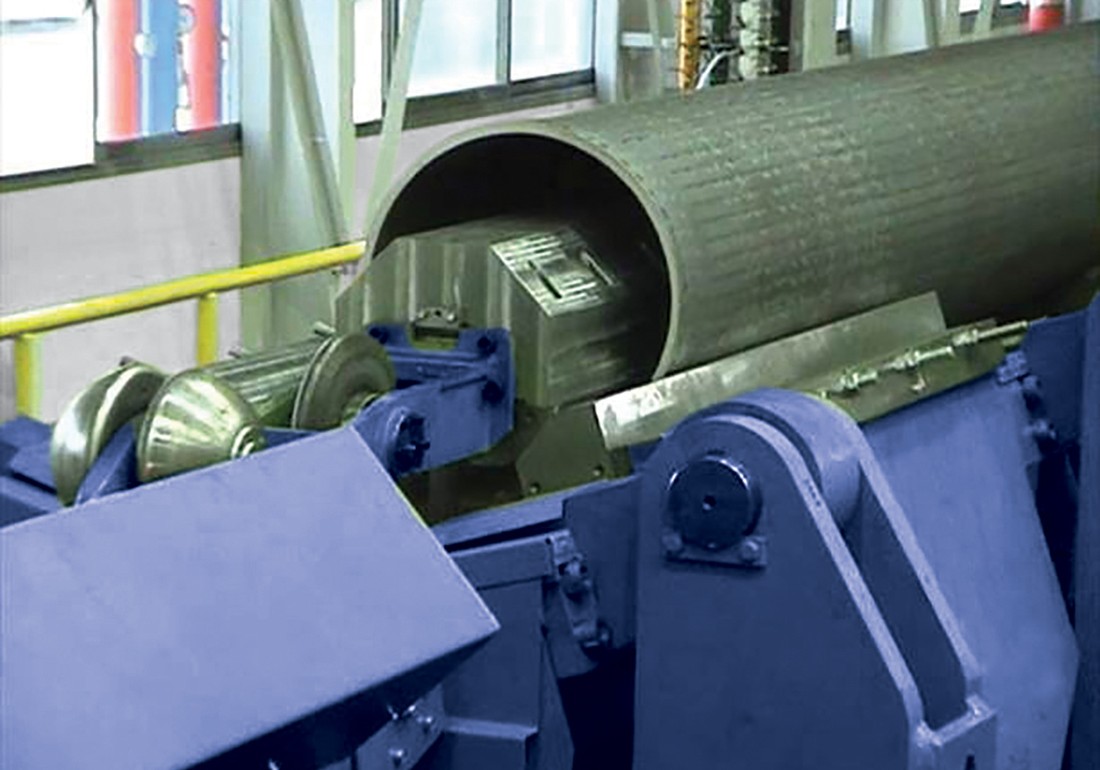

JCO Forming

- Globally proven industry leading technology

- 52,000 kN high capacity bending press

- Deflection compensation eliminating lower tool change

Post Bending

- Post bending utilizing press technology instead of rollers

- 15,000 kN high capacity for bending straight ends up to wall thickness: 45 mm

- Minimized lower tool change

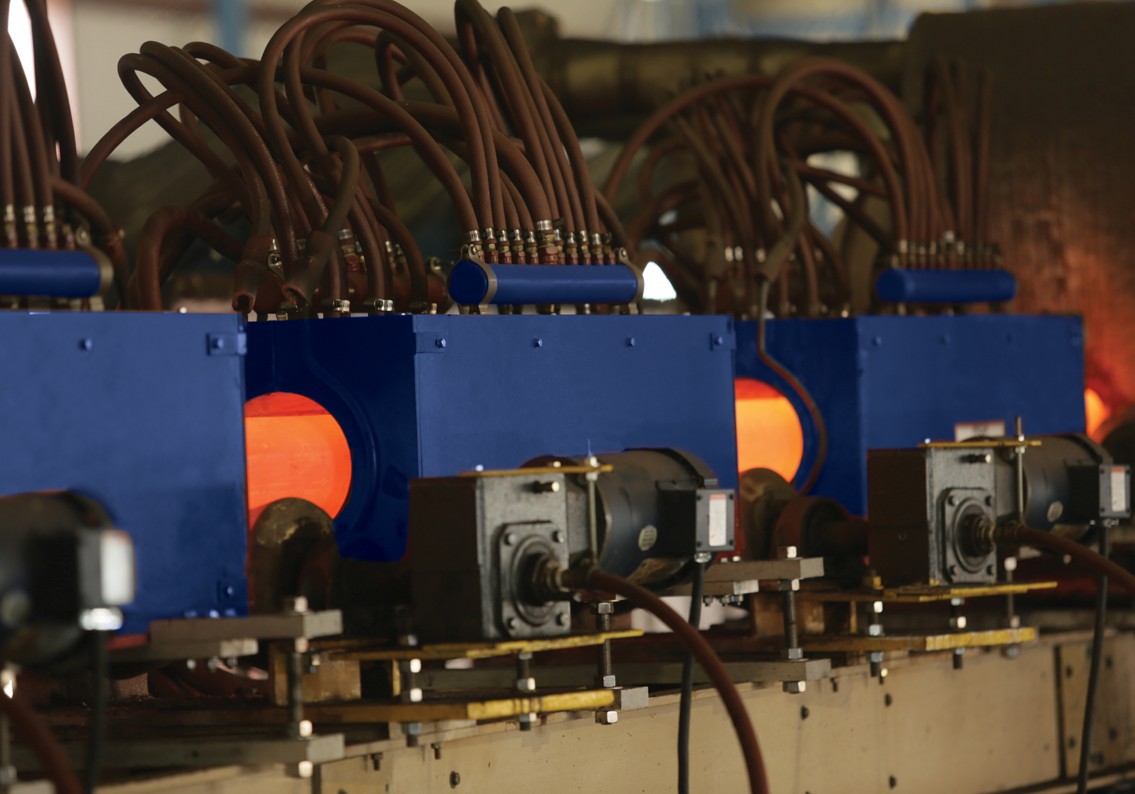

Heat Treatment

- Heat Treatment possibility by two different methods:

- Batch type furnace

- Induction treatment

- PWHT and normalizing in batch type furnace

- Annealing and normalizing for both Carbon, Stainless and Alloy pipes by custom made hi-tech induction equipment

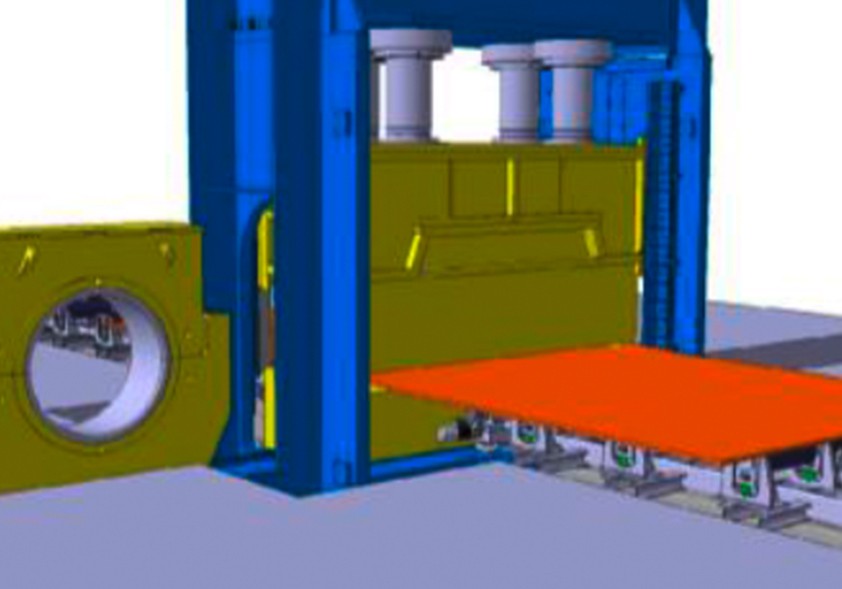

Calibration and Crimping

- Unique design for multi-purpose pressing operation

- 35,000 kN high capacity calibration press

- Multi-purpose functionality for:

- Crimping (for pre-bending)

- Calibration (for roundness)

- Straightening (for banana form)

Ultrasonic Testing

- Globally proven industry leader phased array technology

- Capability of meeting the demanding industry requirements via laser seam tracking

- Sector scan to optimize the angle of incidence and focus length

- Multiple probes for weld zone based on wall thickness

Radiographic Testing

- Digital radiography allowing real time inspection

- YXLON MG 450/4.5 technology

- 450 kvA power to cover complete thickness range

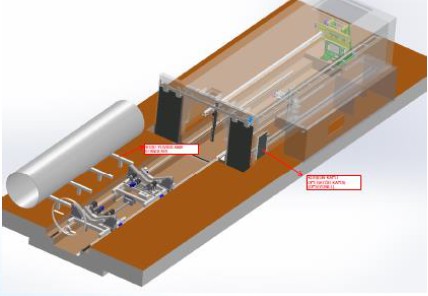

Hydrostatic Testing

- 350 bar maximum testing pressure

- 30,000 kN maximum pressing force

- Moving head and custom engineered air exhausting system