Departments

Welding

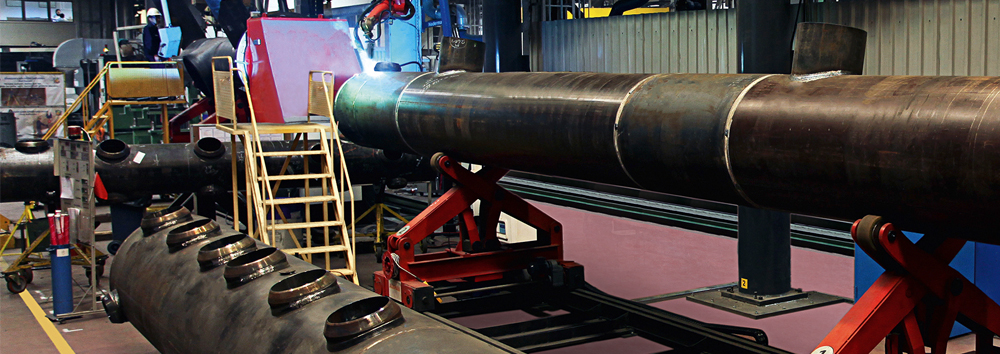

Cimtas Pipe Welders certified according to the international standards are experienced on the welding procedures of GTAW, HotWire, SAW, SMAW, FCAW, STT, GMAW, in combination of manual, orbital and automated processes.

The welders are trained at the in-house welder training center parallel to the welding procedures in theory and in practice.

Procedure qualification records include ferrous and non-ferrous materials like P91, P22, 9%Ni, Alloy 31, Alloy C276, SB209 5083 (Aluminum), SA213TP 409-347, S690, S460NL, 15NiCuNb5, Titanium, Incolloy, Duplex Stainless Steels etc.

R&D including operational excellence and procedure qualification records is executed in our mechanical & metallography laboratory collaborating with authorized inspection companies.

Differentiators;

- 11 EWE – European Welding Engineers

- Welders Training Center

- Certified Mechanical and Metallography Laboratory

- Robotic, Automated and Manual Welding

- 2,350 WPQR/WPAR and 5,950 WPS Preparation

- +15,000 Welders Qualified

- Carbon, Low Alloy and Stainless Steel

- SAW/UP, SMAW/E 111, GTAW/TIG 141, GMAW/MIG&MAG, FCAW , GTAW/TIG Hotwire, STT/RMD, Orbital TIG, Orbital FCAW /Tubular Cored